For a well-known Dutch inland shipping charterer, IJsSoft developed a module that tracks AIS data and visualizes it in a planning tool. The charterer wanted to track not only their own fleet but also the vessels of competitors. This provides a significant advantage in planning and bidding processes.

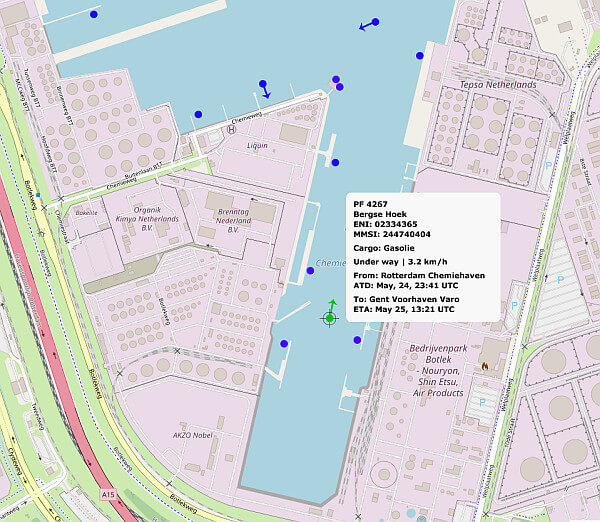

The module retrieves the current data of the vessels in the charterer's own fleet, so they can precisely track where their ships are and what the expected arrival times are at the next port. We enrich the AIS data with information about the ship itself and its cargo. By unlocking this data, crew waiting times are reduced, and interventions are easier by adjusting the vessel’s speed.

The real breakthrough came when the module was expanded to include AIS tracking of competitor vessels. With live insights into where competing ships are located, the charterer could dynamically adjust their own fleet’s speed: sailing faster to reach a port or lock before competitors, or more slowly to save fuel when no time advantage is needed. This strategic foresight allowed them to consistently outmaneuver the competition.

The real benefit of this module became clear when we started tracking competitor vessels too. Because it's immediately clear where those ships are, the charterer can have their vessels sail faster to arrive earlier at a port or be first at a lock. This allows them to outpace the competition. Slower sailing is also an option: if you know you have time to spare, this can save fuel.

After the planning department, the sales team also started using the AIS module. They can bid more competitively on cargo offers from shippers by analyzing patterns in the data. Sometimes a vessel is positioned tactically based on a pattern. If you know competitors have no vessel nearby, you can bid lower or adjust your terms. This led to a reduction in idle hours, higher margins, and better fleet occupancy.

The enriched AIS data in the module is also shared with customers, suppliers, and vessel owners. Customers gain insight into fleet movements, allowing port staff to be deployed more efficiently for loading and unloading. Suppliers, in turn, can better plan bunkering and the delivery of provisions. A win-win for everyone.